Our Factory

"Established over two decades ago, our textile and mattress factory boasts a rich legacy of craftsmanship and expertise. With a strong commitment to quality and innovation, we specialize in the production of premium mattresses and textile products.

Our state-of-the-art facility is equipped with cutting-edge technology, allowing us to design, craft, and deliver exceptional comfort and durability to our valued customers. From material selection to the final product, our factory prioritizes precision, ensuring that every mattress and textile item that bears our name meets the highest standards of quality and satisfaction."

Our Process

01

Design and Planning:

The process starts with designing the mattress. This includes determining the size, type, and specifications of the mattress. Designers consider factors like comfort, support, durability, and cost.

02

Material Selection:

Selecting the right materials is crucial for mattress production. Common materials include foam, innerspring coils, latex, memory foam, and fabric. The choice of materials can greatly affect the mattress's feel and performance.

03

Cutting and Shaping:

Once the materials are selected, they are cut and shaped according to the mattress design. Foam and fabric are cut into the required shapes, and innerspring coils are formed into the mattress core.

04

Assembly:

The various components of the mattress, such as the foam layers, coils, and fabric cover, are assembled in layers. These layers are often glued together or attached using other methods to create the core structure of the mattress.

05

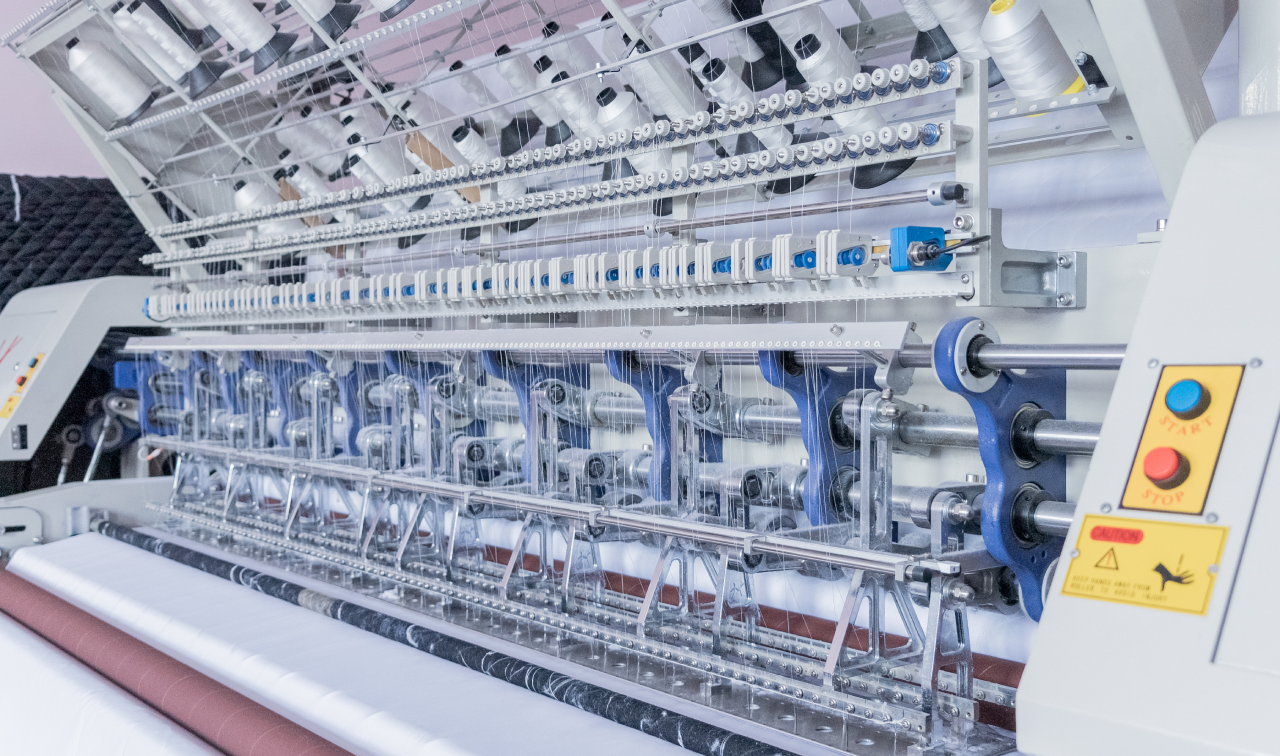

Quilting and Sewing:

The mattress cover, which can be made of various types of fabric, is quilted and sewn to give the mattress its final look. This process can involve adding decorative patterns or stitching.

06

Comfort Layers:

Depending on the mattress design, additional comfort layers like memory foam or latex may be added to enhance comfort and support. These layers are carefully placed within the mattress structure.

07

Tape-Edge Closure:

The mattress cover is typically closed using a tape-edge machine. This machine sews the cover tightly around the mattress, giving it a finished appearance and securing the layers in place.

08

Packaging & Delivery:

Once a mattress passes quality control, it is prepared for packaging. This may involve vacuum-sealing, rolling, or traditional. After this mattresses are packed into boxes or wrapped in plastic, labeled, and prepared for shipping.